Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Faytech docking station PCs in the Endrich line

10 March 2018

Summary :

Today there is a new trend to use smart displays, where the PC is embedded into the housing of the display, and the HMI can be realized by software solution, therefore, the time–tomarket can be very short. When however, there is a requirement for a large size and robust display, and in the same time enough hardware resources to serve the required control functions, it is worth to think of using a combo of a modular industrial PC and an industrial touch display. To complete this challenge Endrich offers a new family of HMI hardware, the Faytech “Docking Station PC” series. Endrich Bauelemente GmbH as one of the strong display providers on the industrial TFT market focuses to offer solutions for advanced human machine interfaces. Today’s HMI design trends no longer accept to interact using push buttons, mechanical switches or keyboards, or getting feedback through status lamps, seven segment or simple monochrome LCD displays, or via acoustics ways. Today it is basic expectation to have high resolution, even sunlight readable color TFT touch displays, with rugged, robust, but slim and professional industrial design. The applied way of solution is determined by the serial quantity, the human resources available for hardware design and the available time to market the product. One can decide to develop an HMI based on own drivers and TFT modules, which is the economic way in case of high numbers of serial production, or use embedded PCs, where the hardware interfacing of the TFT panel is solved.

Conventional TFT displays

To interface a TFT touch panel with the user circuit requires deep knowledge in electronics. The SPI interface used in small display sizes is still quite easy to implement, however for higher sizes and resolutions experience of TTL/RGB or LVDS driving is essential. The designers of electronics devices equipped with traditional TFT touch displays know very well how long it takes to discover and get rid of the hidden hardware and software bugs. When high volume serial production is planned, the engineering hours required for the interface design is usually paid off. When selecting a solution, it is important to pay attention to practical design considerations, quality and environmental conditions. When applying a touch panel, it is possible to choose the cheaper resistive versions, that need pressure to operate, offering advantages in harsh environment, where operators wear gloves, or due to their special profession their finger skin is too thick and dry to operate capacitive touch sensor. On the other hand, the PCAP technology based on the changed parasitic system capacitance caused by the approaching human hand, offers more exact positioning and multi touch features. To switch from one type of display to another requires design changes mainly due to the mechanical connections. When TFTs are required to be replaced caused by no longer available products on the market, users are hardly lucky enough to get the same kind of product with the same connector alignment at a competitor. Same happens if we try to upgrade to larger size or more exclusive version, usually there is a need to redesign the PCB. We introduced earlier Endrich’s own designed iSi50® display family, where all control and signal lines are combined to a single 50 pole connector, which is located exactly at the same position with any members of the family.

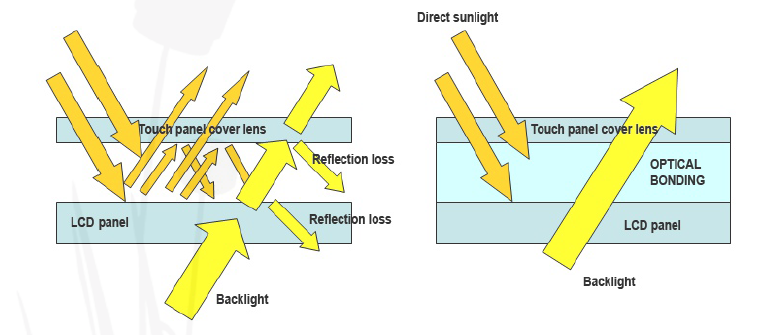

The internal reflection of the construction has a huge influence for display quality. (see on Fig.1 ) When the air gaps appearing between the layers are filled up with a material showing similar refraction index than the layers themselves, there will be less internal reflection of incoming sunlight, which will enhance readability. It can be achieved by using optical bonding, there is no need any longer to have extreme strong backlight even when the display is disposed to direct sunlight in outdoor applications.

Using SCB / ComBoard for HMI

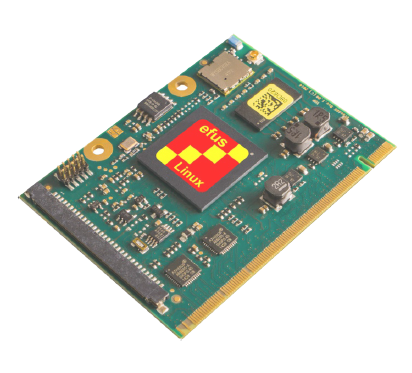

The next level of technologic steps advised by Endrich is to use F&S single board computers, when either the serial quantity does not make it economic to develop own display driver hardware, or the hardware developing skill is missing. In this case interfacing the TFT is solved, the SBC offers direct connectivity to the display. These ARM based industrial grade system on modules either run LUNUX or Windows operating system, and offer less complicated and faster development, hence shorter time-to-market. These embedded systems can be standard single board computers, or even modular versions, that are scalable by using exchangeable computer on modules (COM boards) to host the core components, while the passive mainboard is only for physical connectivity. These boards are located somewhere between microcontroller boards and fully equipped industrial personal computers. They feature the resources of a compact central unit required by a custom designed product with low power consumption meeting industrial environmental expectations, as embedded systems should be like. They offer direct TFT connectivity, and all kind of industrial interfaces.

Smart DisplayModule – SDM

If one may choose DLOGIC’s robust, nicely designed, reliable, affordable and ready to use Smart Display Modules, the development time will be further shortened, therefore the time to market of the finished product can be minimized. This solution offers higher integration level of display solution than SBC+TFT, as the devices contain not only the quality TFT display, the PCAP touch sensor, but also the embedded ARM computer and they are no more open frame solutions. HMI can be realized by only software way, and there is no need to make complicated mechanical solution for providing adequate protection to the HMI as the compact SDM is already protected. The quality of the display is guaranteed by the best choice of panel, applied optical bonding, the safety glass and the metal housing provide robustness, and the high IP protection offers good enough protection against environmental challenges even in harsh circumstances. Maximal size is currently 15”.

„Docking Station” displays and PCs

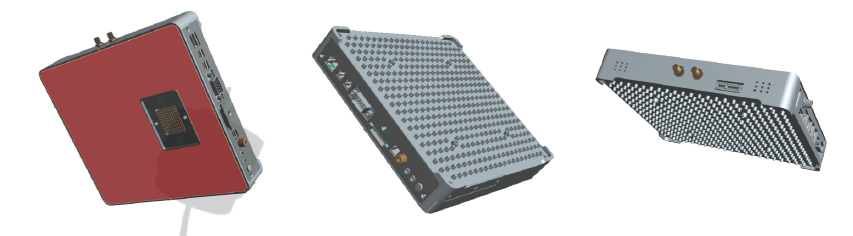

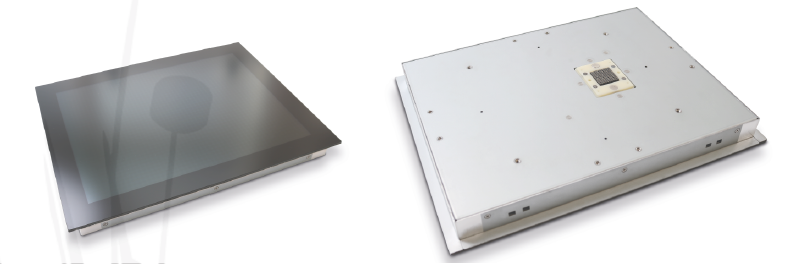

All the solutions above make it possible to realize a state-of-the art HMI, however to design a scalable end-product with easily changeable display in various sizes, embedded PC with different hardware resources to take over all display and control functions, a modular solution is better. The next technological step would then be to use the new Faytech “docking station PC” family, which is characterized by Intel microprocessor based industrial PC, which is docked on the backside of a large industrial LCD touch-display. The „Docking Station” PC itself is a small industrial computer, having Intel® Atom™ Apollo Lake N3350 microprocessor on board. The Intel® HD graphics chipset provides calculation power, the integrated Wi-Fi, several USB ports, the two Ethernet and the RS232/485 serial ports are responsible for data interfacing. There is a special 1 00 pin connector on the top of the PC housing, that makes the system fit to the back of special touch display panel, held by strong magnets and positioning screws. The outer cover of the compact computer (210X185mm) is made of solid but light alumina alloy, offering state-of-the-art, modern appearance, in the meantime providing IP40 protection, a passive cooling to realize long service lifetime. The operating temperature range is -10°C - +60°C.

When powering by 12V DC the power consumption is 28W, which remains below 1W when on standby. The mainboard has 4GB RAM, which can be extended to 8GB, the built-in S-ATA HDD interface gives 6Gb/sec access speed. 2XWLAN and 2XGbit Ethernet take care of networking through the two RJ45 connection available, one of them features power over ethernet (POE) to remotely supply connected ethernet device. In addition to the docking connector there are Display Ports and HDMI for connection additional external monitors. The USB 2.0 & 3 ports as well as RS232 and RS485 make serial interfacing, and 8 general purpose I/O ports are accessible in an additional Rj45 socket. Mass storage can be realized by 2,5” replaceable solid-state drives (SSD). The computer arrives with pre-installed LINUX Ubuntu system, but Windows 1 0 driver support is also possible. As the „Docking LCD” regards, its design follows the design of the PC having the counterpart of the dockingconnector, the magnets and the screw holes. The front panel’s metal frame, the aluminum housing and edge-to-edge cover lens give a modern look to the min 30.000 hours lifetime, energy saving LED backlight equipped HD LCD display, which has a wide viewing angle, and a ten-point PCAP touch sensor. It fully meets the requirement of a stylish human-machine-interface.

The displays are available in 1 5” and 21 .5” sizes, respectively with 4:3 aspect ratio and 1 024×768 SVGA resolution, and 1 6:9 aspect ratio with 1920×1080 pixels resolution (1 6.7M color). The required state of the art human machine interface with own control functions running in kiosk mode can be realized by using Faytech’s docking station PC&LCD combo, running either LINUX or Windows operating system. The HMI can be used as an internet station through its network interfaces, and the required industrial data communication (RS485) and controls (GPIO) are also available. For multimedia functions there are the audio input and the S/PDIF output. The fully scalable display size and PC resources make a real configurable human machine interface, that is possible to realize with either embedded software or web-based programming.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2018/2 | Elektronet : elektronikai informatikai szakfolyóirat, 2018. (27. évf) 2. sz. |

| 2 | Elektronet online | Egy lépéssel közelebb a legfejlettebb ember-gép interfész kialakításához |

| 3 | TechStory M2M | Faytech ipari beágyazott számítógépek |

| 4 | Hungarian version | Faytech ipari beágyazott számítógépek az Endrich kínálatában |

| 5 | New Technology online | Faytech ipari beágyazott számítógépek az Endrich kínálatában |

| 6 | New Technology 2018/2 | 2018. 2.sz. 16-17.o. |