Zoltán Kiss- Area Sales Manager - East Europe - Endrich GmbH.

Passive Matrix OLED displays

13 April 2012

Summary :

The organic light emitting diodes (OLEDs) are getting more and more popular devices in display technologies due to their perfect bright image featuring, fast response and wide viewing angles. By today they are considered as the screens of the future. Some of the engineers however are still afraid of the high cost of this solution. The subject of this article is to show a cost effective solution, the passive matrix OLED technology in comparison with the traditional display techniques.

OLED working principle

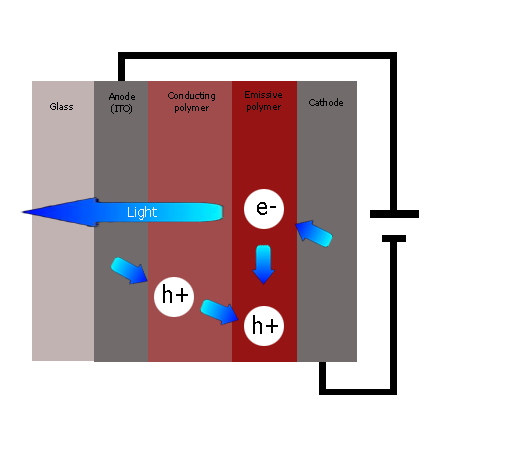

OLED stands for Organic Light Emitting Diode, where the emissive layer is formed by and organic semi conductive compound, emitting light when voltage applied between the two neighboring electrodes. The PMOled is similar to conventional light emitting diodes in terms of working principle. The light emission is generated by the current flows through the device, which excites the electrons to higher energy states, and when falling back to lower states light emission occurs with wavelengths depending on the organic materials used. A typical OLED has a hole transport layer (HTL), an emitting material layer (EML) and an electron transport layer (ETL) in between the two electrodes.

When the voltage applied between the cathode and anode, electrons are injected from cathode and holes injected from anode through the conductive polymer layer to the emissive polymer layer, where the recombination of the electron-hole pairs generate emission, this is the light we can see. With the variety of different chemical structures different emission colors can be obtained. Red, green and blue emitter materials form RGB pixels for full color applications. There are also solutions with combination of white emitters and color filters.

OLED Types

OLEDs are named by the way of controlling or driving the display. Passive matrix OLEDs use a simple control scheme, in which each rows are controlled sequentially, so the pixels are off during the frame time till the next refresh cycle. Therefore the effective voltage applied to the unit must average the signal voltage pulses over several frame times in order to make the pixels brighter, which results a slower response time and a reduction of the maximum contrast ratio than active driving. The addressing of a PMOLED also produces a kind of crosstalk, that produces blurred images because non-selected pixels are driven through a secondary signal-voltage path. Active matrix OLEDs use an active switching element consisting of a thin film transistor (TFT) and contains a storage capacitor for each pixels, which maintain the line pixels it all the time. The active addressing removes the multiplexing limitations. In contrast to passive-matrix OLEDs, AMOLEDs have no inherent limitation in the number of scan lines, and they present fewer cross-talk issues. AMOLEDs consume less power than PMOLEDs, have faster refresh rates and allows to build larger display with higher resolutions. PMOLED materials suffer from lifetime issues caused by the high voltage required and also restricted in resolution and in size, the more lines are used the more voltage is required. AMOLEDs are also more complicated and expensive to produce, so the PMOLED could be a good solution against traditional LCD solutions if the size limitations are acceptable.

OLED comparison to LCD and VFD (Vacuum fluorescent displays)

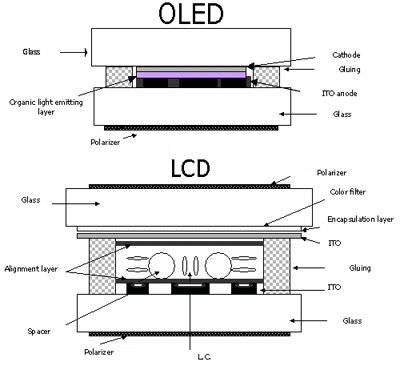

OLED & LCD & VFD displays each offer different characteristics. As the mechanical structure regards, one of the key feature is the thickness of the display. OLED layers are applied to the surface of the glass substrate and this allows the display area to be extended to the edge of the glass. Since OLED is a self emitting device, it does not need a backlight, the display is very thin, while backlit LCDs are thick. VFD needs the mechanical parts mounted around the display frame. Also, VFD needs thick, strong sealing glasses for vacuum encapsulation which makes VFD very thick. OLED advantage is the thin and light weight construction.

As the optical and electronic properties regard, OLED has a far higher resolution with a faster response time, bright saturated colors, a wider viewing angle, superior brightness, and high contrast in comparison with LCD & VFD displays. The OLED technology uses less power than conventional VFD, thus being environmentally friendly display for the most consumer and industry equipments. LCDs are not emissive devices, do not produce light, they just pass or block light reflected from an external backlighting system, which requires usually more energy. (Except reflective LCD modules, which do not have backlight, but here other properties, like contrast and viewing angle are worst) Thanks to OLEDs’ organic pixels emitting light, it delivers a pure native color, avoiding the use of color filters. Also because of the lack of backlighting OLEDs can display deep black levels and in especially low ambient light conditions, such as a dark room, OLEDs can achieve a very high contrast ratio. As the LCD produces image by controlling the alignment of liquid crystal molecules in order to pass or block reflecting or generated backlight it has a certain response time, which is definitively higher than the self emitting OLED devices, which respond much faster, therefore no afterimage remain in quick moving graphics. OLED display can be produced with a single polarizer layer for allowing a clear readable message even when wearing Polaroid glasses.

The comparison is summarized in the table shown on figure 4 for a Raystar pmOLED.

| Comparison Example Character COB 16*02 | OLED | LCD | VFD |

|---|---|---|---|

|

|

|

|

| View Angle | H:175 V:175 | H:60 V:60 | H:160 V:160 |

| Contrast | 2000:1 | 10:1 | 1000:1 |

| Lifetime | 20-100k óra | 30k~50k óra | 30k óra |

| Thickness (with component) | 6.90 mm | 9.70 mm | 14.40 mm |

| Sunlight Readable | Optional | No | No |

| Resolution (Dot Gap) | 0.02*0.02 mm | 0.05*0.05 mm | 0.02~0.05*0.02~0.05 mm |

| Operation Temp. | -40°C ~ +80°C | -20°C ~ +70°C | -40°C ~ +80°C |

| Power Consumed @100% lighting ratio | 200 mW | 500 mW | 680 mW |

| Weight | 22g | 30g | 35~130g |

| Response Time | At +25°C : 10μ Sec. At -20°C : 10μ Sec. | At +25°C : 0.25 Sec. At -20°C : 4 Sec. | At +25°C : 10μ Sec. At -20°C : 10μ Sec. |

| Driving Voltage | 3~5V | 3V or 5V | 35V |

| Character Font | 4 types in one IC | 1 types in one IC | Only 1 or 2 types in one IC |

Issues with OLEDs

As we could see above there are many advantages of using passive matrix OLEDs against traditional LCDs in the engineering applications. To make the picture bright we need to talk about the negative considerations as well. The OLED production costs are still very high, so whenever the size restrictions of pmOLEDs are acceptable, those modules are preferred to be used instead of traditional LCD modules. The biggest technical problem with OLEDs is the limited lifetime of the organic materials, especially the blue emitting ones, but this is developing now and the gap between LCD and OLED lifetime is getting smaller. Water can damage the organic materials, therefore improved sealing processes are involved into the mass production. We should also mention one more possible issue with OLEDs, this is the sensitivity for prolonged exposure of UV light, which however could be eliminated by using an simple UV blocking filter as a clear plastic layer on the glass.

OLED technology is used in commercial applications such as displays for mobile phones and portable digital media players, car radios and digital cameras among others, favoring the high light output for even sunlight readability and the low power drain, and because of the intermittent usage, the lifespan is less of an issue.

| Share on Facebook | Share on LinkedIn |

References

This article has been published on the following locations:

| # | Media | Link |

|---|---|---|

| 1 | Elektronet 2012/3 | Elektronet : elektronikai informatikai szakfolyóirat, 2012. (21. évf.) 3. sz. 21-22. old. |

| 2 | Elektronet online | Passzív mátrix OLED kijelzők |

| 3 | Hungarian version | Passzív mátrix OLED kijelzők |

| 4 | Techstory M2M | Passzív mátrix OLED kijelzők |